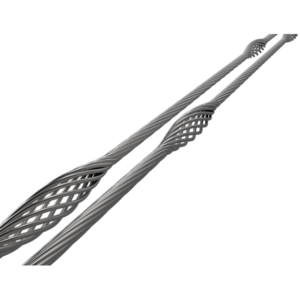

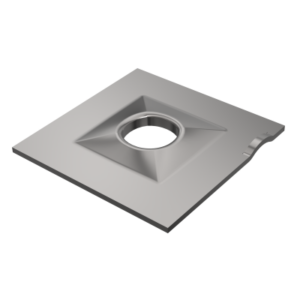

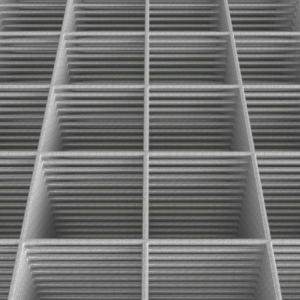

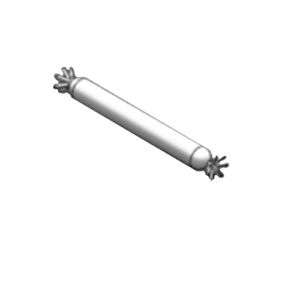

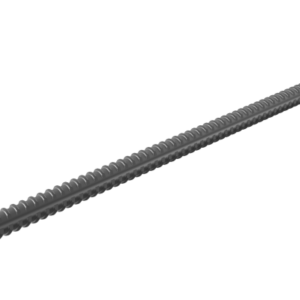

Split Set Mining Systems, manufacture, distribute and support the original IR Split Set Friction Rock Stabilisers and a complete range of ground support products, including Resin Bolts, Bearing Plates, Cable Bolts, Mine Mesh and Core Storage Systems.

Since the introduction of the IR Split Set Stabiliser in 1977, many millions have been used in over 50 countries on seven continents around the world.

Split Set Mining Systems offers ongoing technical support in the way of operator awareness training for the correct installation procedure for ground support products supplied by Split Set Mining Systems.

With branch offices throughout Australia, Split Set Mining is always conveniently placed to service its customers.