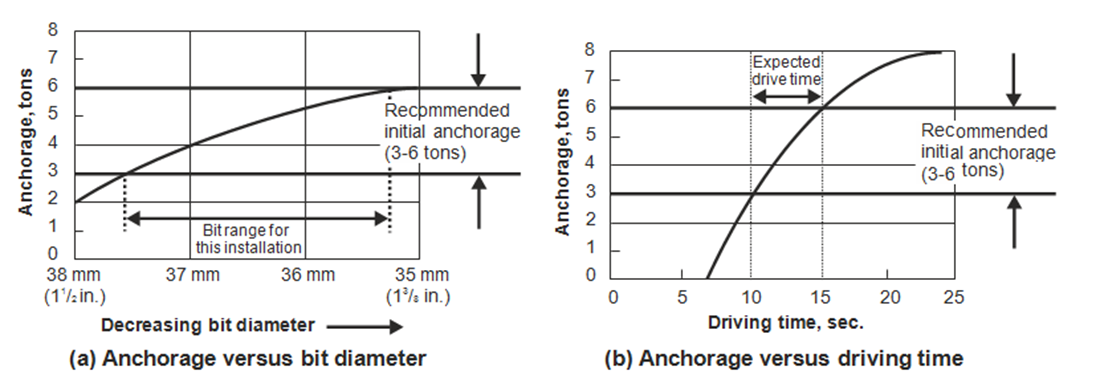

To select the correct drill bit diameter for meeting the recommended initial anchorage of 3 to 6 tons, drill several holes with bit diameters ranging from /8 to 1-1/2 inch (35 to 38 mm).

- Drill each hole at least 2 inches (5 cm) longer than the bolt

- Number each hole and record the bit size.

In soft ground, a bit may drill a hole larger than its diameter. In hard abrasive ground, the hole may be the same diameter as the bit.

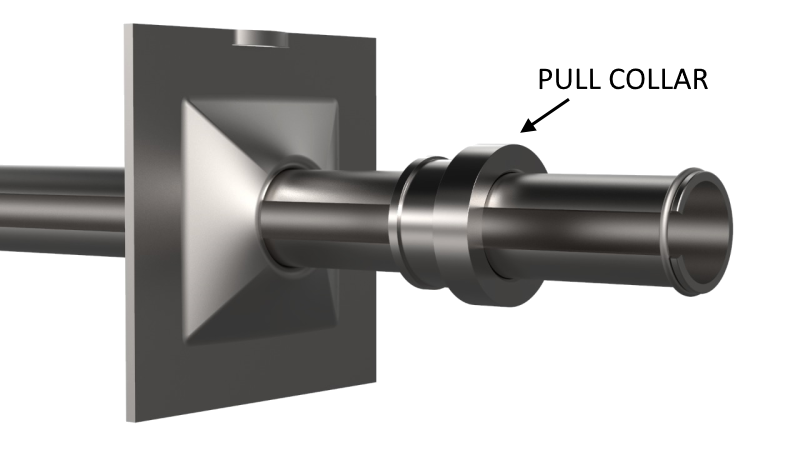

Drive into each hole an SS-39 Split Set stabilizer fitted with a pull collar as shown.

- Record the driving time for each After insertion, observe the amount of slot closure inside each stabilizer.

To determine anchorage, perform a pull test.

- Align the pull tester with the stabilizer, and pressurize it until the stabilizer slips in the

- Watch to be sure that it is actually the stabilizer that has (When building up the pull load on the stabilizer, various adjustments may occur such as realignment of the tester housing, bearing plate settling, or localized rock crushing. These must notbe mistaken for tube slippage.)

Once the bolt has slipped in the hole, pressurize the tester pump until the bolt slips again. The same pull load should cause subsequent slippage.