- Model SS-39 Split Set stabilizers are 39 mm in diameter.

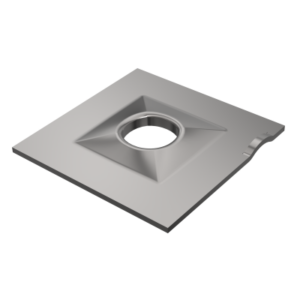

- Tubes and plates are available standard or galvanized.

- Code stampings on the tube show its size, date and place of manufacture, and heat lot of steel.

- Split Set Mining Systems quality management system for Split Set products has been certified to the ISO-9002 international quality standard.

SS39 Split Set Stabilisers are generally most suitable in softer ground types.

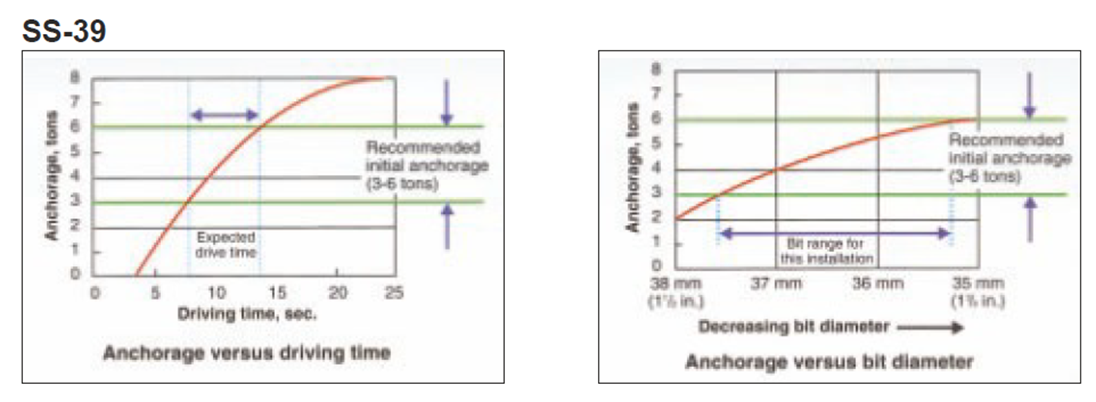

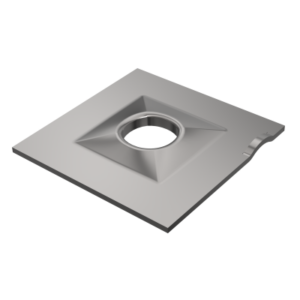

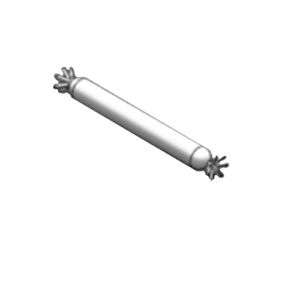

The Split Set stabiliser is a slotted steel tube, with one end tapered for easy insertion into a drill hole. The other end has a welded ring flange to hold the bearing plate.

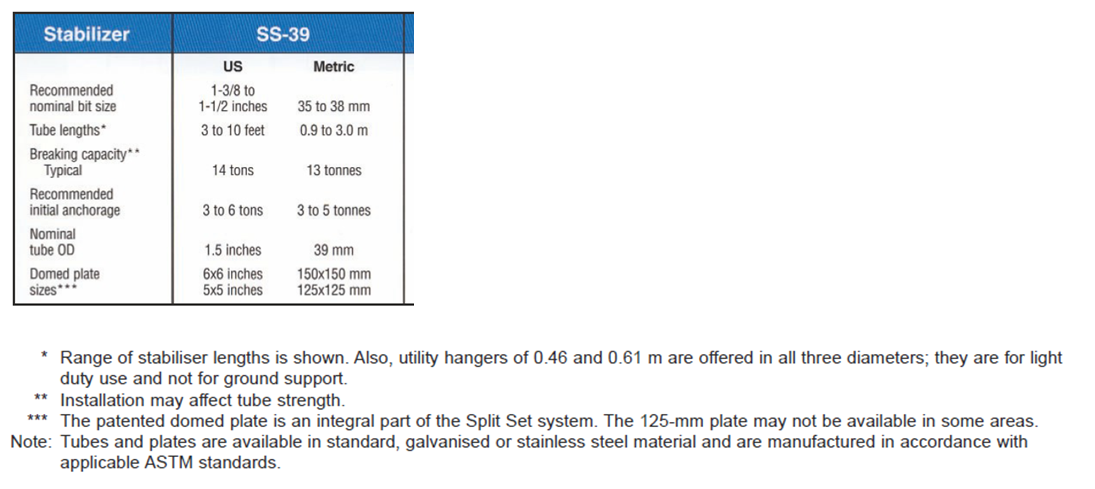

The stabiliser is inserted into a hole slightly smaller in diameter than the tube, using a simple driver tool fitted to the drill. As the tube enters, its diameter is compressed and the slot partially closes. This exerts radial forces along the length of contact with the rock, providing the friction which holds the rock together. The driving force of the drill actively loads the bearing plate against the rock.